본문

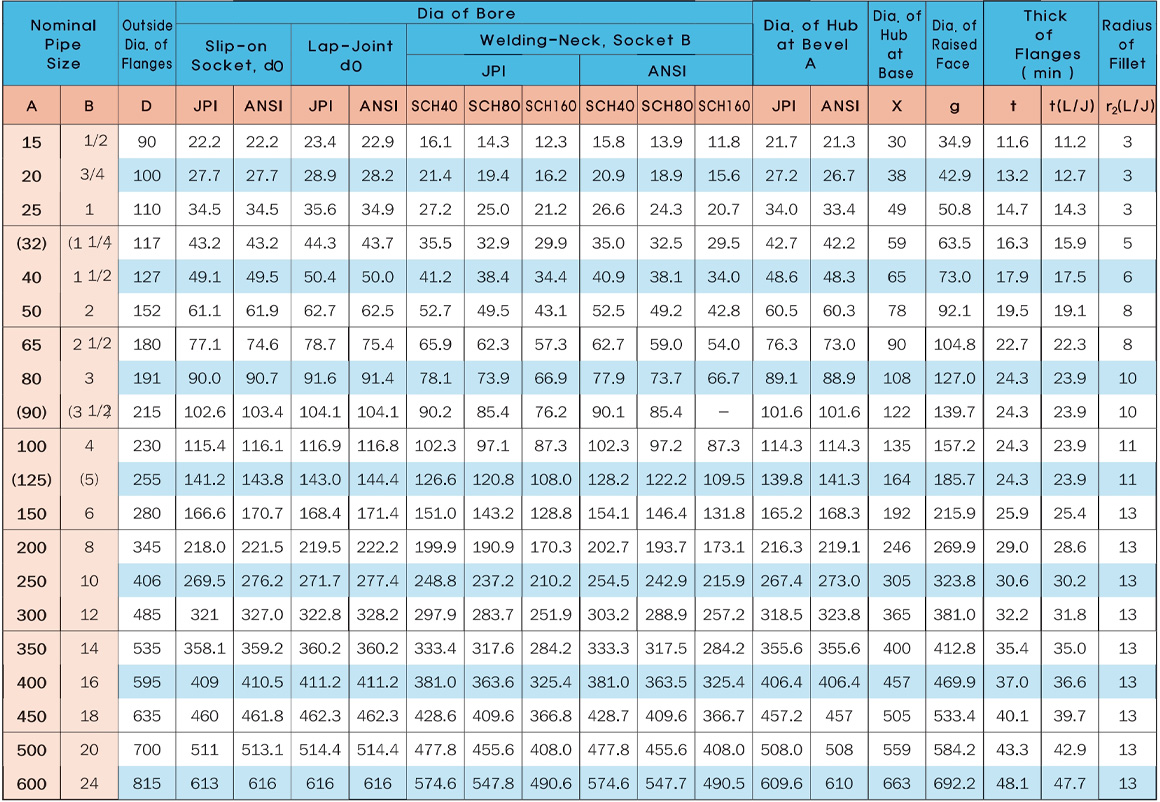

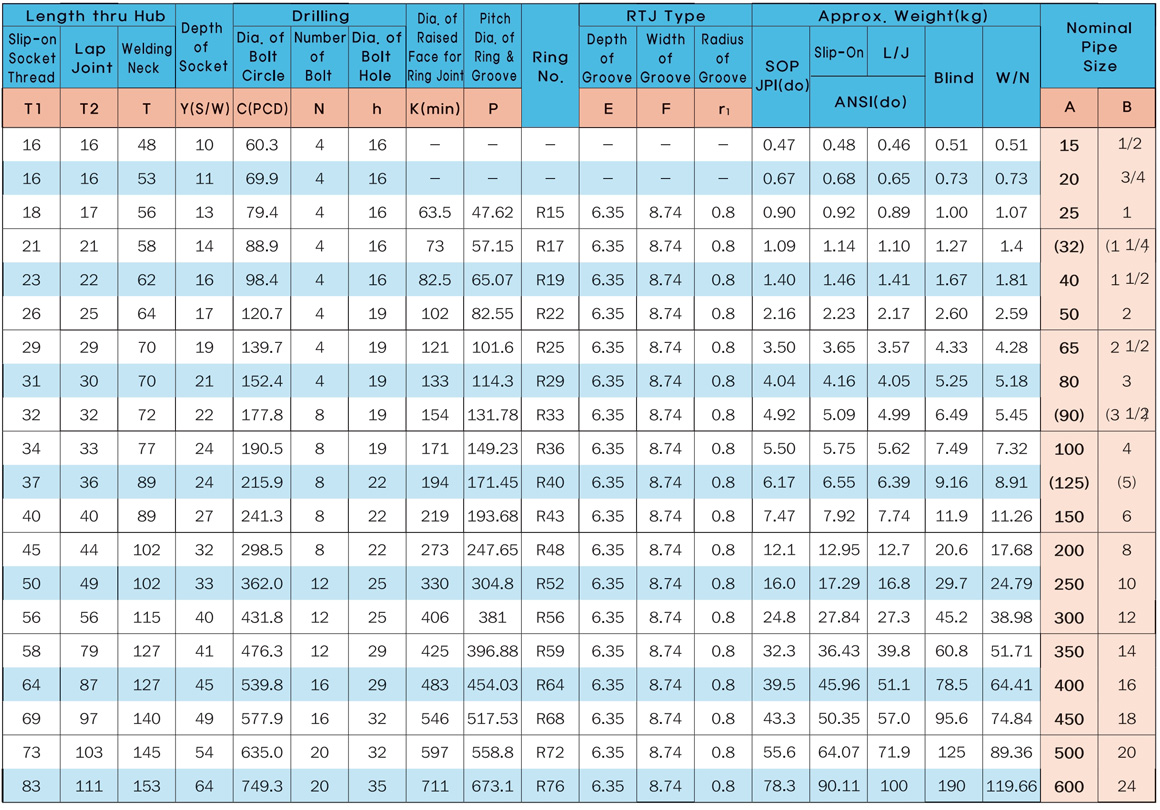

CLASS 150 FLANGESJIP-7S-15-81 & ASME B 16.5

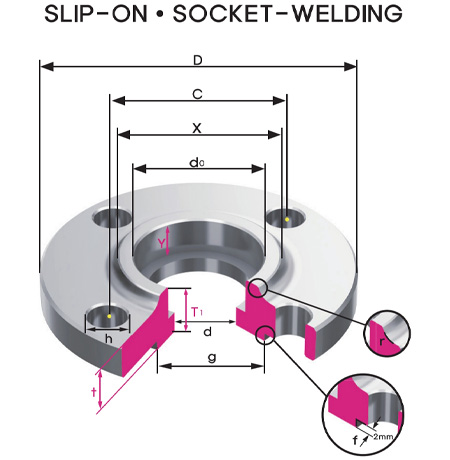

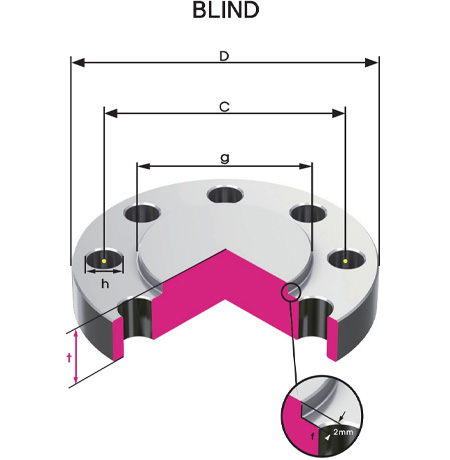

- This dimension is for large end of hub, which may be straight or tapered. Taper shall not exceed 7 deg on threaded, slip-on, socket- welding, and lapped flanges. This dimension is defined as the diameter at the intersecion the hub taper and the back face of the flange.

- The minimum thickness of these loose flanges, in sizes NPS 31/2 and smaller, is slightly greater than the thickness of flange on fittings which are reinforced by being cast integral with the body of the fitting.

- The flat face may be either the full t dimension of thickness plus 2mm of the t dimension thickness without the raised face height.

- Dimensions in bore of welding neck, socket welding correspond to the inside diameters of pipe as given in ASME B36.10M for standard Wall

pipe. Thickness of Standard Wall is the same as Schedule 40 in sizes NPS 10 and smaller.

Tolerances in page 63 apply. These bore sizes are furnished unless otherwise specified by the purchaser. - Height of raised portion is equal to the depth of groove dimension E, but is not subjected to the tolerances for E, Former full-face contour may be used.